Resins for Plastic Fabrication

Choosing the right resin for your product and industry is essential, as it can impact product quality, performance, and suitability. The choice of resin influences how products respond to mechanical stresses, temperature, and other environmental conditions. Additionally, it can define the product’s appearance, compliance with regulations, and even compatibility with manufacturing processes. Failing to choose the proper resin can result in product failure, higher costs, or the inability to meet project requirements.

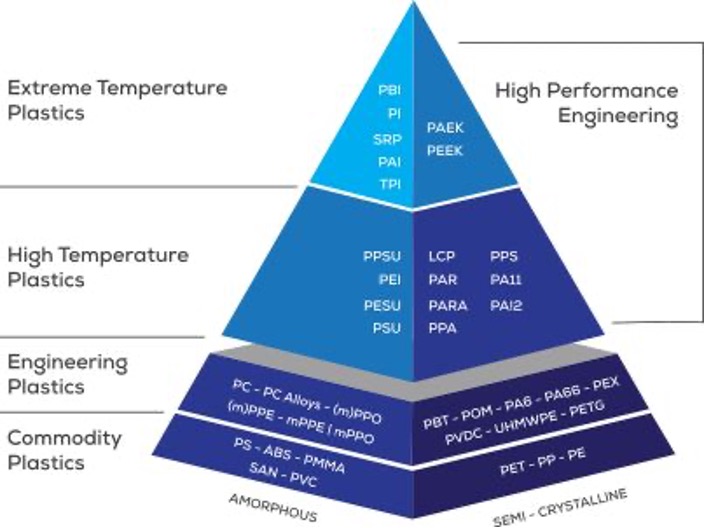

From commodity plastics to extreme-temperature plastics, learn about the resins we work with below and discover how we can help you determine the best option for your next project.

Our List of Resins

Looking to start your next plastic manufacturing project? AdvancTEK has expertise working with a variety of resins, so we can create a reliable solution for your application. Even within a single resin family, selecting the appropriate material can greatly impact the final result. Our material selection expertise enables us to provide solutions that guarantee superior outcomes.

The resins we work with include:

- ABS

- Polypropylene

- TPO

- PVC – flexible

- Nylon 6

- Nylon 6/6

- Nylon 12

- Polyurethane

- Amodel

- Polycarbonate

- ASA

- PC/ABS

- HIPS

- HDPE

- LDPE

- POM / Acetal

- Ultem

- PBT

- PMMA / Acrylic

- PEEK

- TPU / TPE

- PPO

- PET

Why We’ve Chosen These Resins

The resins we use are known for having high strength and impact resistance, as well as portability and processing flexibility. Additionally, engineered resins offer consistency and repeatability in the production of parts, reducing failures.

Depending on the type, some resins provide thermal stability and corrosion resistance for increased longevity in varied applications. For example, PVC, POM, and PET can resist chemicals, oils, and cleaning solvents. Meanwhile, resins like PEEK, Ultem, and PPO tolerate high operating temperatures.

Our wide selection of available resins makes it easy to find just what you need and transform the material into functional parts with the help of injection molding.

AdvancTEK also offers compression molding or thermoforming if the product or process warrants. We can provide a variety of material and design solutions utilizing these processes.

Reach Out with Questions!

Our team is ready to discuss resins in plastic manufacturing. Contact us today to get the conversation started.