Leading the Way as a

Reaction Injection Molding Company

AdvancTEK is at the forefront of Reaction Injection Molding (RIM) technology. Our expertise as a reaction injection molding manufacturer spans from luxurious, soft-touch interior components to durable, high-impact exterior parts. With three unique RIM systems, we can tailor solutions for a vast array of polyurethane composite applications. Our partnerships across diverse industries have enabled us to turn innovative RIM concepts into reality, ensuring the highest standards of quality and performance.

- IATF 16949 and ISO 14001 certified

- Tier one supplier across automotive, marine, recreational vehicles, and health industries

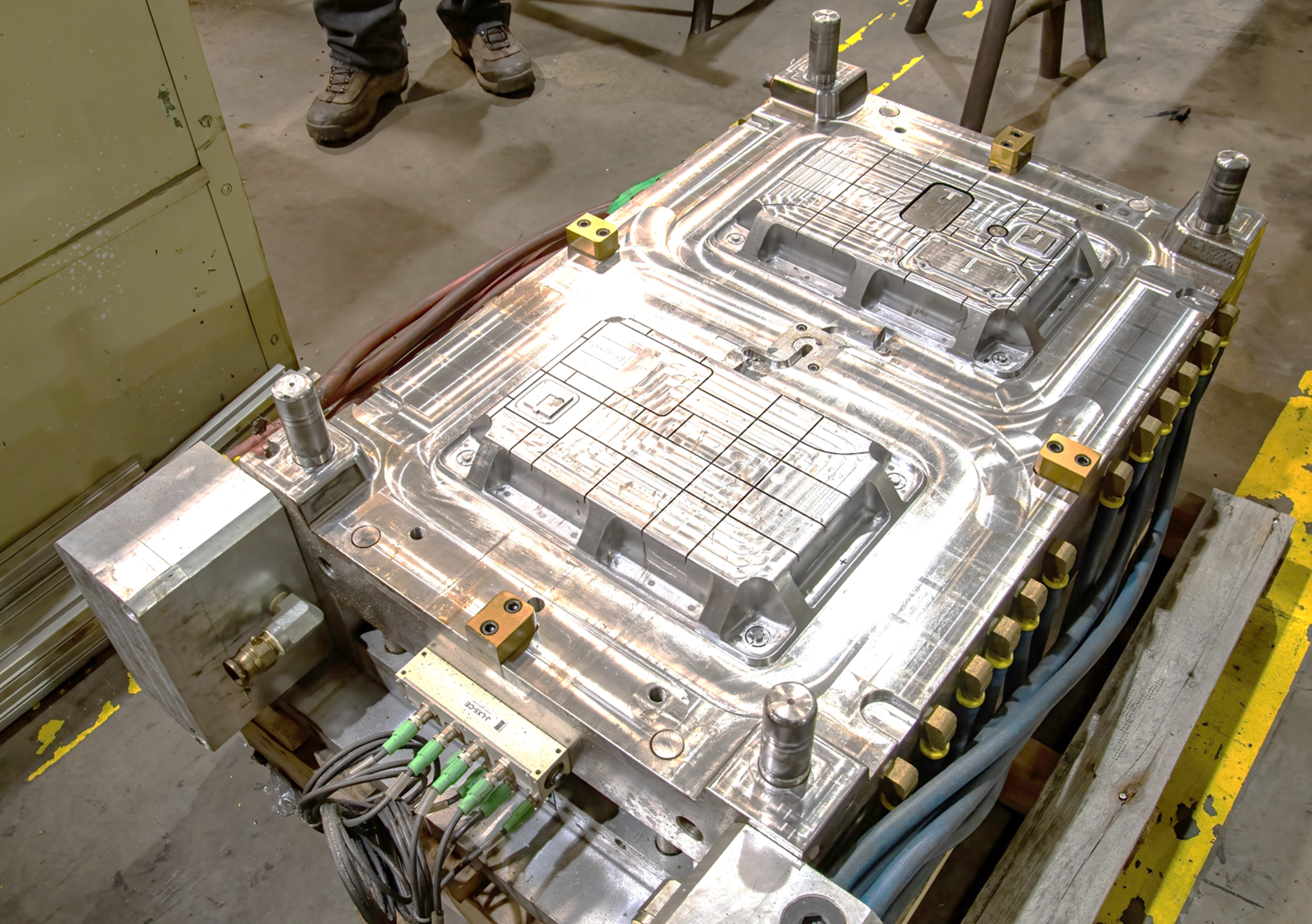

- Mold clamps up to 3′ x 10′ capacity

- In-house staffed quality lab

- Complete design and engineering support for the entire reaction injection molding process

Reaction Injection Molding – Explained

Reaction injection molding is a versatile manufacturing process that combines two reactive components, mixed together and injected into a mold under high pressure. As the polymer expands, it fills the mold cavity and cures to form a finished product. This process allows for extensive material customization, making it suitable for a wide range of applications. RIM offers significant design flexibility, like injection molding, but with a lower tooling investment, making it an attractive option for many projects.

Why You Should Choose a Custom Reaction Injection Molding Manufacturer for Your Parts

- Large, lightweight parts – RIM produces components with a high strength-to-weight ratio, making it ideal for large, lightweight parts.

- Superior acoustic and thermal properties – The material’s inherent properties provide excellent sound absorption and thermal insulation.

- Tunable density and thickness – RIM materials can be adjusted to meet specific application needs from soft-touch to rigid, high-impact characteristics.

- Thermal stability – Reaction injection molding parts maintain their properties across a wide range of temperatures, ensuring durability in demanding environments.

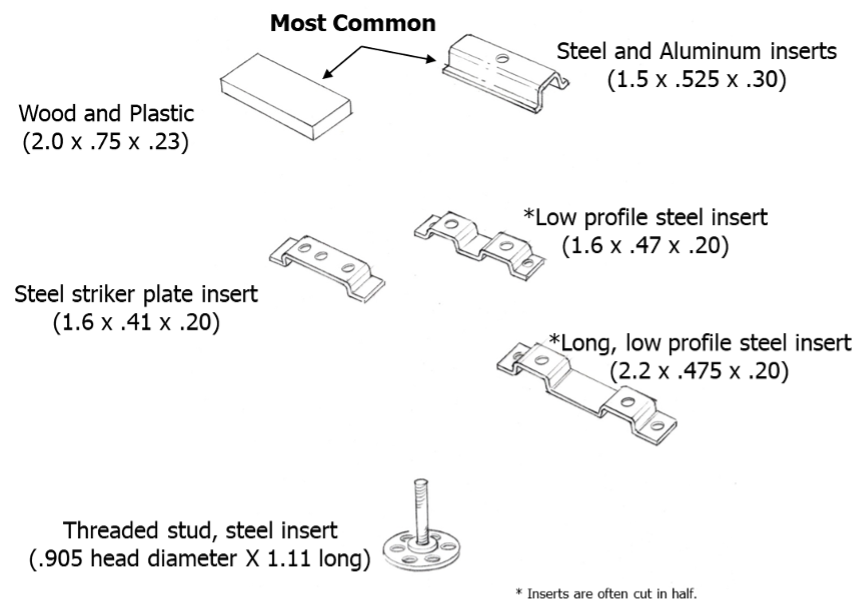

- B-side features and insert encapsulation – RIM allows for the incorporation of complex geometries and embedded inserts, enhancing functionality and design.

- Cost-effective tooling – With a lower tooling investment than traditional injection molding, RIM is cost-effective for both low- and medium-volume production runs.

- Rapid prototyping – Quickly develop and test prototypes, accelerating the product development cycle.

- Complete design freedom – RIM’s flexibility enables innovative designs and complex shapes that are difficult to achieve with other manufacturing processes.

When RIM Is the Right Solution for Your Project

- Working with a custom reaction injection molding manufacturer is an excellent solution for producing large, lightweight parts that require a high strength-to-weight ratio and extensive customization options.

- RIM’s unique process allows for the creation of components with complex geometries, including varying wall thicknesses and intricate attachment features, making it ideal for parts that demand both design flexibility and structural integrity.

- This method is particularly well-suited for low- to mid-volume production runs, typically ranging from 500 to 10,000 units annually, depending on part size.

- The process of reaction injection molding has comparatively low tooling costs, making it a cost-effective choice for projects that require complex designs but do not justify the expense of traditional high-volume molding methods.

Creating RIM Parts: From Concept to Completion

- The tool (typically aluminum but can be epoxy) is opened to prepare the surfaces.

- Tool surfaces are prepared with a mold release to ensure material does not bond to the cavity or core.

- The cavity of the mold is painted, or a cover material is inserted into the mold.

- If inserts or other components are required, they are loaded into the mold.

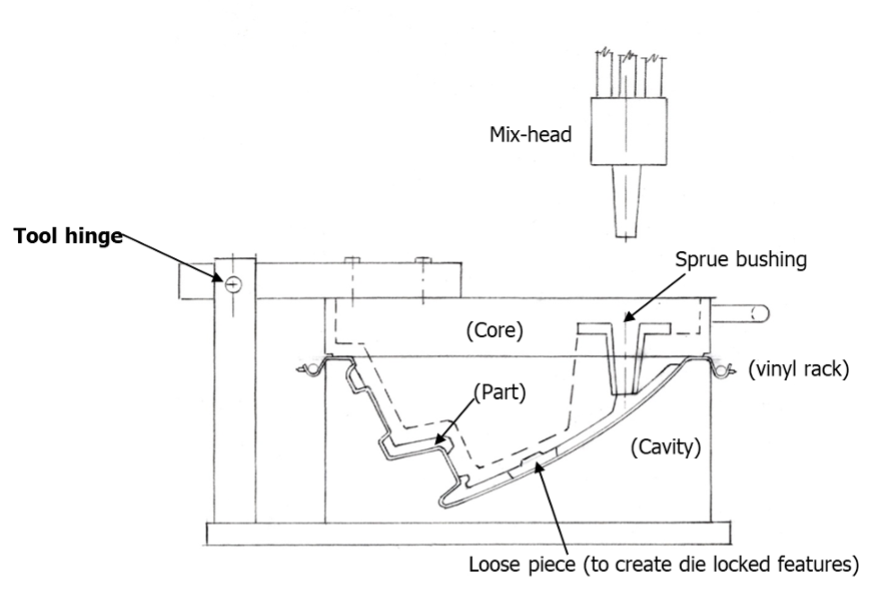

- Once the cavity of the mold is prepared, the material can be injected into the mold. There are two methods of introducing the material to the mold:

- Open pour method – The mold is open, and the material is poured or injected into the cavity. The mold must then be quickly closed.

- Closed pour method – The mold is closed, and the material is injected into the mold utilizing a mix head.

- Once the material is in the mold, there is a curing period for the material to harden and stabilize.

- Once the material is cured, the mold can be opened, and the part can be removed.

- Depending upon the material and product application, the part can then go to a trim process and other value-added steps.

Our Custom RIM Systems

As a reaction injection molding manufacturer, AdvancTEK offers specialized systems, each tailored to meet specific application requirements.

Vinyl-Clad Rigid (VCR)

Ideal for applications requiring a durable, high-quality surface finish, our VCR system combines the strength of rigid polyurethane with the aesthetic appeal of a vinyl surface. This system is perfect for interior components that must look good and perform under stress.

I-Skin/T-Skin

Our I-Skin and T-Skin systems provide a soft-touch feel with excellent durability. These systems are commonly used in automotive interiors and consumer products where comfort and aesthetics are paramount.

Microcellular Urethane (MCU)

MCU systems offer a fine cellular structure that provides excellent cushioning and impact resistance. This system is ideal for applications such as seating, padding, and protective equipment.

RIM Applications

Reaction Injection Molding is versatile and can be applied to a wide range of industries and products:

- Armrests

- Bumpers and fascias

- Fender liners

- Padding / bumpers for medical carts

- Instrument panels / dashes

-

- Medical device covers

Problems We Solve as a Custom Reaction Injection Molding Manufacturer

- Attachment and Assembly Challenges – Attaching parts to an assembly can be challenging, especially when rust and corrosion are concerns. Fortunately, this problem can be solved by choosing nonferrous attachment methods, such as wood, plastic, or aluminum, which can be used to prevent rust and corrosion, ensuring a durable and reliable connection.

- Surface finish requirements – With RIM parts, you can achieve a variety of a-surface finishes, including overmolded and soft-touch surfaces.

- Cost-effective tooling – High tooling costs can be a challenge, but RIM’s low-pressure process reduces tool construction requirements, allowing the use of cast aluminum, epoxy, or even wood for prototyping.

“They do what they say, they’re honest, and responsive. They also do what they say in a timely fashion.”

Our Expertise as a Reaction Injection Molding Company

As a reaction injection molding manufacturer, we bring years of experience as a tier-one supplier to a wide range of industries, including fields like automotive, marine, recreational vehicles, and healthcare. At AdvancTEK, our deep expertise spans a variety of foam systems and applications, allowing us to deliver the most effective solutions for your RIM product needs. Our capabilities include molding clamps up to 3′ x 10′ and the flexibility to produce parts using both rigid and flexible foam systems.

Our reaction injection molding company offers a variety of surface finishes, a wide range of attachment schemes, and virtually unlimited part thickness variations. Additionally, we provide in-house part design services and collaborate closely with customers to reduce complexity, part count, and costs for both existing and new programs. Our comprehensive value-added services include painting, assembly, line set, sequencing, and kitting, all supported by a fully staffed quality lab for in-house inspections and product validation.

Frequently Asked Questions

What are your certifications?

AdvancTEK is IATF 16949 and ISO 14001 certified. As part of our APQP process, we also collaborate with customers early and often to define CSRs (customer-specific requirements) to ensure we are meeting all customer requirements.

Can you offer design and engineering support?

Yes! We have a team of design, product, process, and manufacturing engineers that work with customers at various stages of their development cycle. We offer full design and development services, in addition to DFM (design for manufacturability) and product design recommendations. As part of any proposal development, we will identify initial part design issues that may affect manufacturability, cost, quality, or other key items.

How can I get a quote?

Our sales team would be happy to connect with you about reaction injection molding parts. Use one of the contact forms on this website or call the number at the top of the page. Each quote is custom-tailored to meet your specific requirements.

Which AdvancTEK facilities offer reaction injection molding?

We proudly offer reaction injection molding at our Saltillo, Mexico, and Concord, North Carolina plants.