Top-Notch

Design & Development Services

AdvancTEK has built a reputation for developing custom, fast, and robust engineering solutions that address our customers’ unique challenges. We’re your premier design partner, leveraging our extensive engineering resources, global partnerships, and diverse knowledge of processes, materials, and markets to provide you with the competitive advantage you require to succeed.

Conceptualization

- Idea generation

- Benchmarking

- Styling

- Industrial design

- Surfacing & modeling

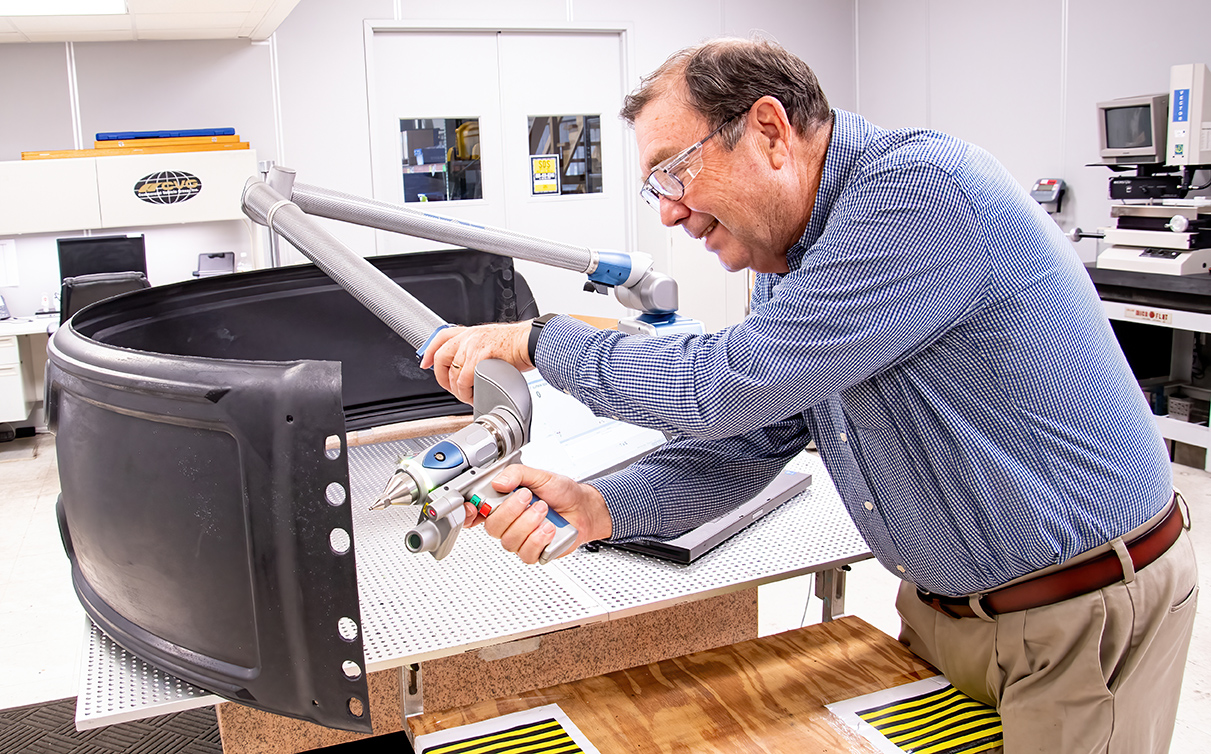

Product Development

- Design & development

- Prototyping

- Testing & validation

- Tool design

- Dimensional management

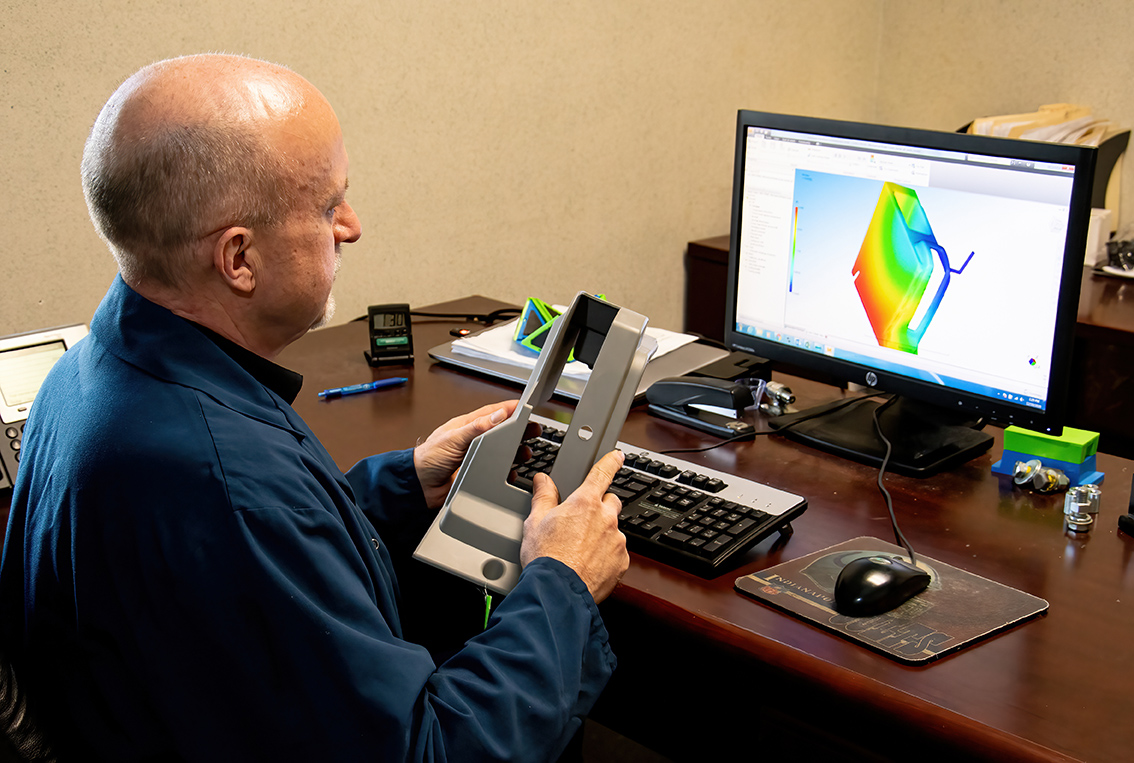

Design Optimization

- CAE/FEA

- FMEA

- Value analysis/value engineering (VA/VE)

- Continuous improvement

- Design for Manufacturability (DFM)

Material Selection

- Apply the correct material for each application

- Leverage relationships to obtain best material and price

- Development of technical requirements

- DVP & R development

DFM Analysis

- Reduce costs

- Improved manufacturability

- Increased speed to market

- Part consolidation

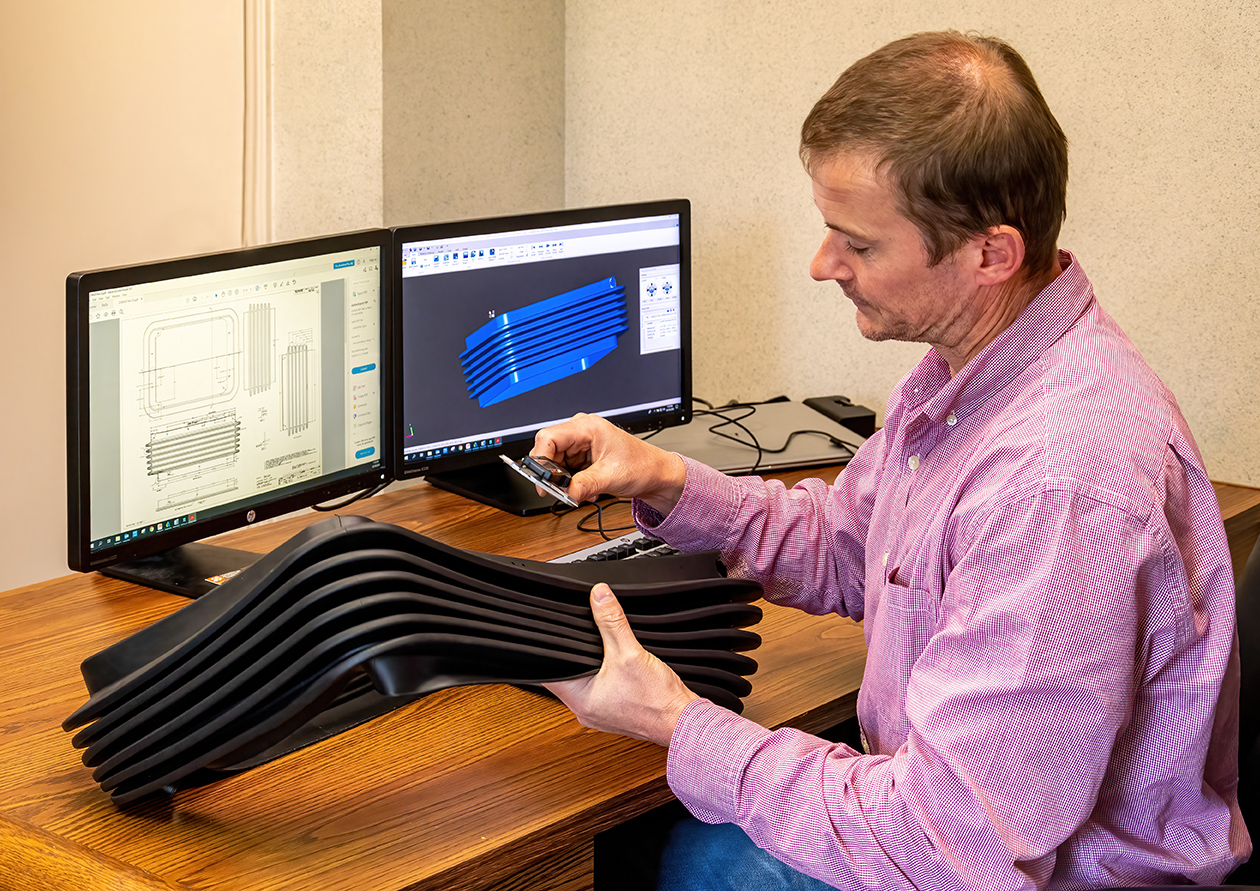

Rapid Prototyping

- Additive manufacturing

- Rapid tooling

- Pull ahead tooling

- Evaluate form, fit, and function of physical properties

Mold Flow Simulations

- Optimize part design

- Reduce risk of warpage

- Assess cooling channel efficiency

- Cycle time optimization

- Address manufacturing challenges

Tool Design

- In-house tool design

- Collaborative part & tool design process

- Optimize material selection

- Evaluate and optimize primary and secondary part processing