Injection Molding

Nothing Short of Precision Injection Molding

Injection molding is our expertise. We have decades of experience teaming with customers in various markets to help them successfully bring their projects to life by providing them with design, tooling, and production expertise.

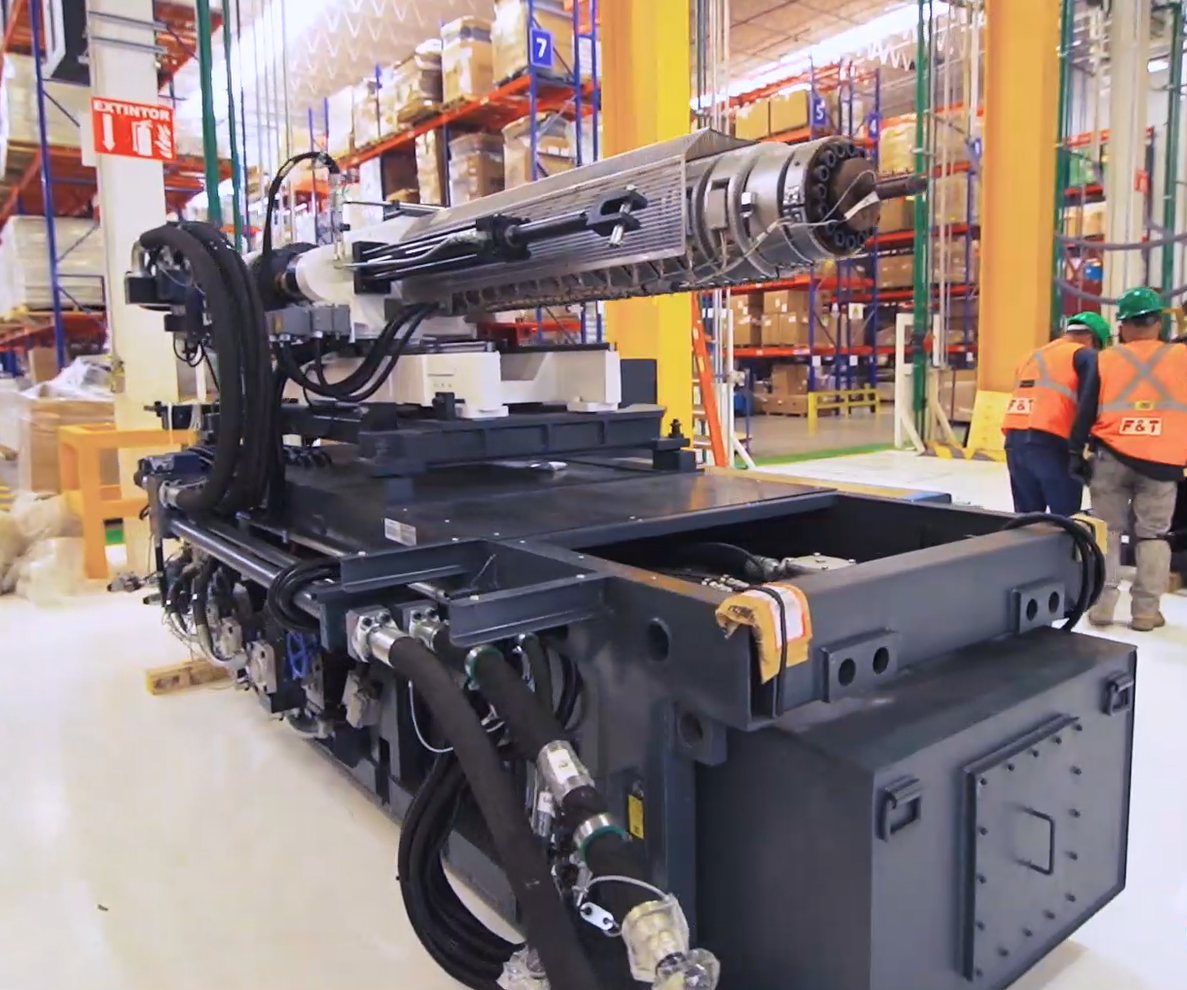

We offer a wide range of injection molding capabilities spanning from 65T to 3500T and provide solutions for large-part molding, gas-assist molding, in-mold labeling, insert molding, and conventional injection molding.

What is Injection Molding?

Injection Molding

Injection molding is a great option for higher-volume plastic molding projects. Melted plastic resin is injected into a mold to produce high-quality and often complex components. Parts often have “A” and “B” side design features that are functional, structural, or aesthetic. Although tooling investment is higher than thermoforming, the price per unit is much lower than many other plastic manufacturing processes.

Advantages and Benefits of Injection Molding

- Complex, intricate parts

- Fast cycle time

- Low piece price

- High production volumes

- Tight tolerances

- A & B side design features

- Insert molding

- Gas-assist molding

- Robotics and automation

- Integrated attachment features

- Varying part thickness

- Wide range of materials

- Ability to decorate

- Minimal waste