Plastic Injection Molding Manufacturer

Nothing Short of Precision Injection Molding

Injection molding is a manufacturing process used to produce parts by injecting molten material, typically plastic, into a mold cavity for shaping, then solidifying it into a final product – it also happens to be our expertise.

As one of the most popular plastic manufacturing processes, injection molding is widely used for different applications across diverse markets. Backed by decades of experience, AdvancTEK provides injection molding solutions of varying sizes and volumes for industries like:

- Industrial

- Medical

- Battery and energy storage

- Telecommunications

- Powersports and recreation

- Construction and agriculture

We also specialize in producing large plastic parts for your bigger projects.

Is Injection Molding Right for You?

With its ability to mold B-side features, achieve tight tolerances, and be produced in a wide range of basic to highly engineered materials and colors, injection molding offers a great deal of part design freedom, which can help designers solve a variety of challenges for their products.

Injection Molding Explained

Injection molding is a great option for higher-volume plastic molding projects. Melted plastic resin is injected into a mold to produce high-quality and often complex components. Parts often have “A” and “B” side design features that are functional, structural, or aesthetic.There are several benefits to injection molding, but the suitability of this process is entirely dependent on the details of project.

Advantages

- High production rates – The speed and efficiency of the process are ideal for large-quantity orders. We are able to produce parts quickly with very little variation.

- Speed – Plastic injection molding manufacturers produce a large quantity of parts per hour, and cycle times are significantly faster than processes like thermoforming or RIM.

- Repeatability – The plastic used in injection molding is forced into the mold under immense pressure. Due to this, a large amount of detail and complexity can be incorporated into these parts. Action can be incorporated into the tool design to allow for die lock features to be designed into the part. Plus, parts can be easily replicated, over and over again.

- Cost-effectiveness – Plastic injection molding solutions tend to have a lower price per unit than many other plastic manufacturing processes.

- Minimal waste production – Injection molding has a very low scrap rate, producing only a small amount of scrap compared to other processes. Additionally, much of the material is recyclable, making it an environmentally friendly option for many industries.

- Lightweight – Modern thermoplastics used in injection molding are inherently lighter than metals, yet can provide comparable strength and durability. Materials such as ABS, nylon, and polycarbonate are engineered to be lightweight while meeting demanding structural requirement.

Disadvantages

- High initial tooling costs make this process more suitable for high-volume production runs

Plastic Injection Molding Myths

There are several misconceptions surrounding large part molding. One common mistake is oversimplifying the required tonnage. Factors like material type, wall thickness, and gating play crucial roles in determining the size of the machine needed. Our custom plastic injection molding company conducts detailed mold flow analysis and simulations to optimize each project, ensuring the most efficient use of equipment.

Another often overlooked aspect is the cost and logistics of shipping large molds. Moving these molds requires careful planning, the right type of trailer, and cranes for loading and unloading. AdvancTEK’s extensive experience and logistics capabilities enable effective management of these challenges, which is why we are among the best plastic injection molding manufacturers to work with.

If injection molding doesn’t sound like the right fit for you, explore our other manufacturing processes, reaction injection molding (RIM) and thermoforming.

Our Process as a Plastic Injection Molding Company

For AdvancTEK, the injection molding process starts before a tool is ever built or a part is ever made. We specialize in partnering with customers early in their development cycle to ensure we provide guidance on part design and manufacturability. This leads to improved costs and efficiencies in the long run.

However, once the tool is built and we’re ready to mold, the process starts with heating the plastic pellets into molten material, which is then injected into a tool to form to the desired shape. The part is ejected and often robotically picked from the machine and delivered to the operator. Then, the operator will trim the gate (if necessary), inspect the part, and label it. AdvancTEK can also provide value add processes once the part is molded. We support assembly, ultrasonic welding, kitting, and sequencing

Materials Used for Injection Molding

The best material for your product will depend on its desired properties and application, budget constraints, and environmental factors. Weeding through all the hundreds of material options can be daunting, but that’s what AdvancTEK is here for!

Our team provides expert advice on material selection based on these considerations. AdvancTEK maintains an inventory of several different plastics ready for your next injection molding project, including:

- Polypropylene (PP)

- Thermoplastic Polyolefin (TPO)

- Acrylonitrile Butadiene Styrene (ABS)

- Polycarbonate and Acrylonitrile Butadiene Styrene (PC/ABS)

- Acrylonitrile Styrene Acrylate (ASA)

- Nylon

- Flexible Polyvinyl Chloride (PVC)

- Polyethylene (PE)

- High-density Polyethylene (HDPE)

- Glass-filled or mineral-filled varieties

- UL94 V-0 rated materials

- Chemical foaming agents

Our Capabilities as a Custom Plastic Injection Molding Company

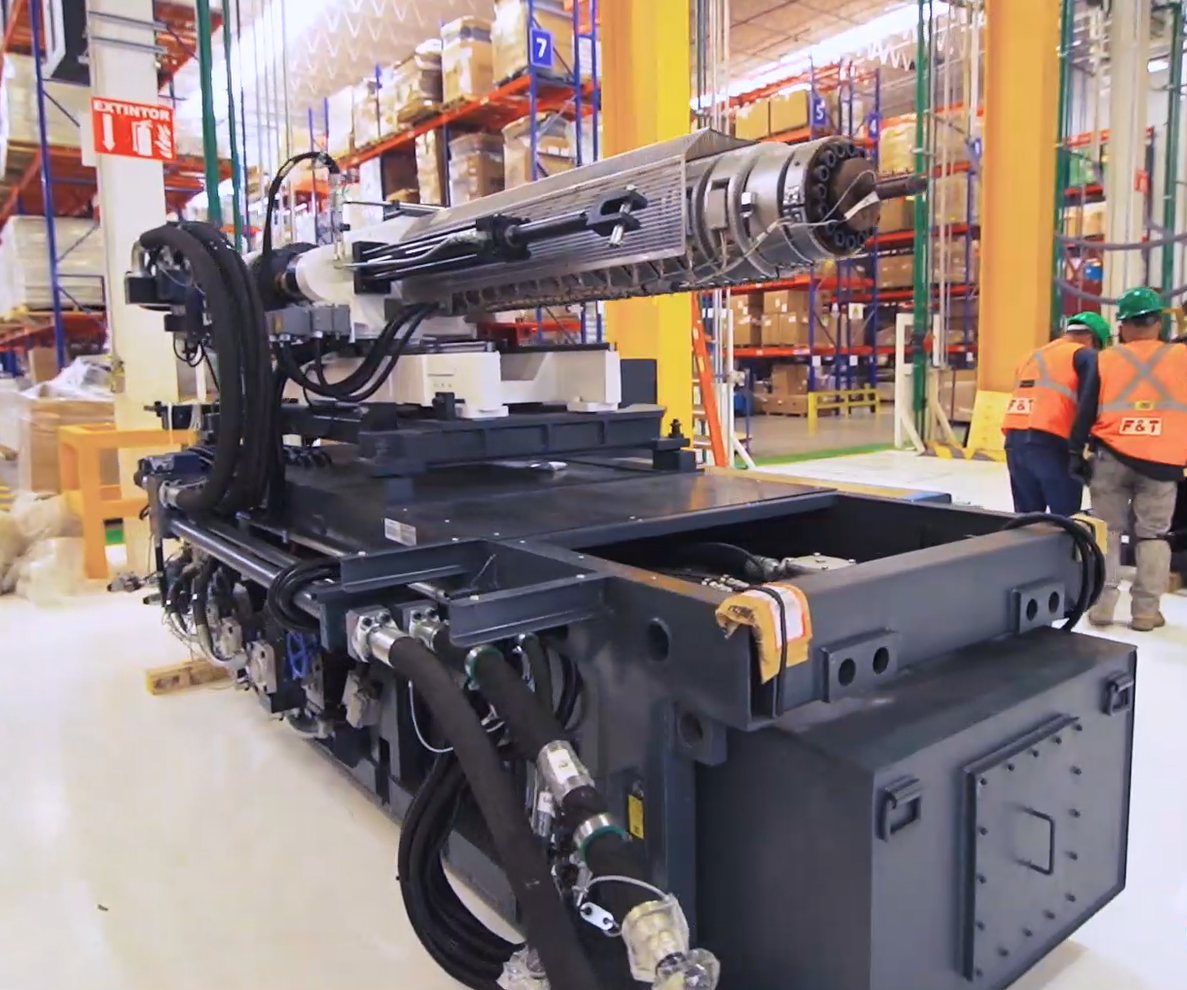

As a reflection of our industry knowledge, we’re pleased to offer an extensive list of molding capabilities that ensure we consistently meet the needs of our customers. Currently, we operate presses spanning from 65T to 3500T and provide solutions for large-part molding, gas-assist molding, in-mold labeling, insert molding, and conventional injection molding.

At AdvancTEK, we are always seeking opportunities to better equip ourselves to help customers reach new heights of success. Therefore, we are willing to invest in larger or unique capital equipment if needed to help bring your project to fruition.

See Our Expertise in Action

Looking for reliable plastic injection molding solutions? Look no further than AdvancTEK. Our portfolio of projects is diverse, and we want to highlight one example today.

We manufacture a complex and flexible PVC suspension cover for complete seats that are assembled by our sister company, National Seating. The tool used to produce this part has multiple actions and collapsible core and cavity blocks to achieve the geometry required. The part is then robotically picked from the machine and placed on a conveyor, which delivers it to the operator.

Our Facility Is an Injection Molding Powerhouse

AdvancTEK boasts an impressive lineup of 11 injection molding machines over 1,450 tons, including four machines with capacities exceeding 3,000 tons and a maximum capability of 3,500 tons. Our crane capacities, ranging up to 40 tons in Mexico, further enable us to manage the heavy molds required for large parts.

There are several misconceptions surrounding large part molding. One common mistake is oversimplifying the required tonnage. Factors like material type, wall thickness, and gating play crucial roles in determining the size of the machine needed. Our team at AdvancTEK conducts detailed mold flow analysis and simulations to optimize each project, ensuring the most efficient use of equipment.

Success Stories

We have successfully leveraged this equipment to tackle unique molding challenges. For instance, a customer required a very large one-piece part that initially seemed to need 4,000 tons of clamping force. By strategically adding more sequentially activated drops and adjusting wall thickness, we reduced the tonnage requirement to 900 tons, demonstrating our ability to optimize the molding process for efficiency and cost savings.

Another often overlooked aspect is the cost and logistics of shipping large molds. Moving these molds requires careful planning, the right type of trailer, and cranes for loading and unloading. AdvancTEK’s extensive experience and logistics capabilities help manage these challenges effectively.

Benefits to Partnering with AdvancTEK

We have successfully leveraged our equipment to tackle unique molding challenges. For instance, a customer required a very large, one-piece part that initially seemed to need 4,000 tons of clamping force. By strategically adding more sequentially activated drops and adjusting wall thickness, we reduced the tonnage requirement to 900 tons, demonstrating our ability to optimize the molding process for efficiency and cost savings.

“They do what they say, they’re honest, and responsive. They also do what they say in a timely fashion. I just really started working with these guys and they’re very responsive.”

(From an anonymous responder of a survey our team sent out)

FAQs About Our Abilities as a Custom Injection Molding Manufacturer

What size presses do you have?

Between our two injection molding sites, AdvancTEK has 65T – 3500T molding, with the largest machines located in Saltillo, Mexico. One of our 3500T machines also has a shot size of 70 lb, which is one of the largest in North America.

What are your certifications?

AdvancTEK is IATF 16949 and ISO 14001 certified. As part of our APQP process, we also collaborate with customers early and often to define CSRs (customer specific requirements) to ensure we are meeting all customer requirements.

Can you offer design and engineering support?

Yes! We have a team of design, product, process, and manufacturing engineers who work with customers at various stages of their development cycle. We offer full design and development services, in addition to DFM (design for manufacturability) and product design recommendations. As part of any proposal development, we will identify initial part design issues that may affect manufacturability, cost, quality, or other key items.

Do you run engineered materials?

Yes! We are a custom manufacturer and are very accustomed to both commodity and highly engineered grades of materials. To name a few, we currently use PP, TPO, HDPE, ASA, PC-ABS, and Nylon, in addition to glass- or mineral-filled materials, chemically foamed materials, and gas-assisted materials.

How can I get a quote?

Our sales team would be happy to connect with you. Use one of the contact forms on this website or call the number at the top of the page. Each quote is custom-tailored to meet your specific requirements.