Insert Injection Molding Solutions for Enhanced Part Performance

Precision Insert Molding for Complex Applications

Insert injection molding allows manufacturers to integrate separate components directly into molded parts, creating stronger, more functional products while reducing assembly time and costs. Whether you need threaded inserts for durability, metal reinforcements for strength, or RFID components for logistics tracking, our insert molding expertise delivers consistent, high-quality results.

- Facilities in Concord and Saltillo specializing in insert molding

- Extensive experience across automotive, medical, agriculture, and consumer product industries

- Advanced robotics and engineering capabilities for complex insert applications

- Full-service support from design through production launch

- Expertise in all standard molding processes including structural foam injection molding, gas counterpressure, and gas-assisted molding

What Is Insert Injection Molding?

Insert injection molding in the simplest of terms is inserting a separate component into an injection mold and molding over it to achieve a desired function or property. Typically insert injection molding and overmolding are used interchangeably.

Objects inserted into the mold prior to injection may be other molded parts, metal plates or bars for strength/stiffness, threaded inserts, brackets or other objects needed to form a part that meets part functional, structural and/or cosmetic goals.

This versatile manufacturing process enables the creation of complex, multi-material parts in a single molding operation, streamlining production and improving part performance.

Common Custom Insert Molding Applications

Some products even have RFID components insert/overmolded into the part. RFID is commonly used in moldings that are planned for use in logistics applications.

Rigid glass filled parts such as various handles or grips are often inserted into a secondary molded and overmolded with TPU/TPE materials to improve feel and grip. Insert molding can be accomplished with all the standard molding processes: structural foam, gas counterpressure, straight injection, as well as internal and external gas assisted parts.

Critical Considerations for Successful Custom Insert Molding

Material Compatibility and Selection

Insert molding can be done with nearly all molding grades of material from commodity grades to highly engineered resins. When molding one specific resin over another there needs to be compatibility to ensure adhesion between the materials. That can be accomplished by either inherent chemical bonding of the resins or by designing for a mechanical bond. Some resins used for overmolding a part inserted into the mold are specially formulated to improve adhesion.

Insert Placement and Retention

Threaded inserts used in insert molding are most commonly designed for that purpose and the tooling is designed to retain them in place during the molding process.

An important consideration for insert molding is assuring the inserted components stay in place in the mold during the injection stage and the remaining portion of the molding operation. This can be done by a variety of methods from simple friction to mechanical engagement or in some cases even magnetics. AdvancTEK has extensive experience engineering this critical factor into mold construction.

Automation and Production Volume

With proper machine safety lock outs in place, the item being inserted into the mold may be done by an operator within overall cycle. More commonly the item is placed in the mold robotically. Robotics are more commonly used when inserting molding with large molds or higher production volume applications. It is also more common when there are many inserts or other items being loaded into the mold before mold close and injection.

Problems Solved Through Insert Injection Molding

Injection molding inserts addresses critical manufacturing challenges that can compromise part quality and increase production costs. For example, use it solve or prevent a large number of potential problems; part warp, stiffness, overall strength, and offers an increased level of flexibility for the part designer.

Key Solutions

- Secondary post molding operations can often be reduced or even eliminated.

- Overmolded threaded inserts can, in some cases, provide better and more consistent rotational torque strength and pull out performance vs. inserts installed post molding.

- By integrating components during the molding process, manufacturers can reduce assembly steps, minimize handling damage, and improve overall part consistency.

The AdvancTEK Advantage: Consistent Quality Every Time

The insert molding process allows for consistent and repeatable process controls. Using post-secondary processes for insert loading can result in variation related to operator training, environmental changes and part geometry issues caused by warp or other factors.

Utilizing the injection mold press and process parameters allows AdvancTEK to reduce variables and variation in the process. This gives our customers a consistent, quality part every time.

Core Benefits of the Insert Molding Process

- Reduced Variation – Eliminate inconsistencies from operator training and environmental factors

- Process Control – Precise parameters ensure repeatable results

- Quality Assurance: Consistent parts meet specifications every production run

- Cost Efficiency – Minimize secondary operations and labor costs

Industries We Serve: Proven Insert Molding Expertise

Variations of insert injection molding/overmolding are used across a wide variety of industries and a core competency at AdvancTEK. From automotive/large transportation products, agriculture products, power sports, hand tools, grab handles and a wide variety medical, consumer applications and more.

Our insert molding capabilities support diverse applications:

- Automotive & Transportation – Structural components, interior trim, functional assemblies

- Medical Devices – Precision instruments, diagnostic equipment, patient care products

- Agriculture – Durable equipment components, weather-resistant assemblies

- Power Sports – Performance parts, control grips, safety components

- Hand Tools – Ergonomic handles, reinforced tool bodies

- Consumer Products – Grab handles, household items, electronic enclosures

From Design to Delivery: Your Insert Molding Partner

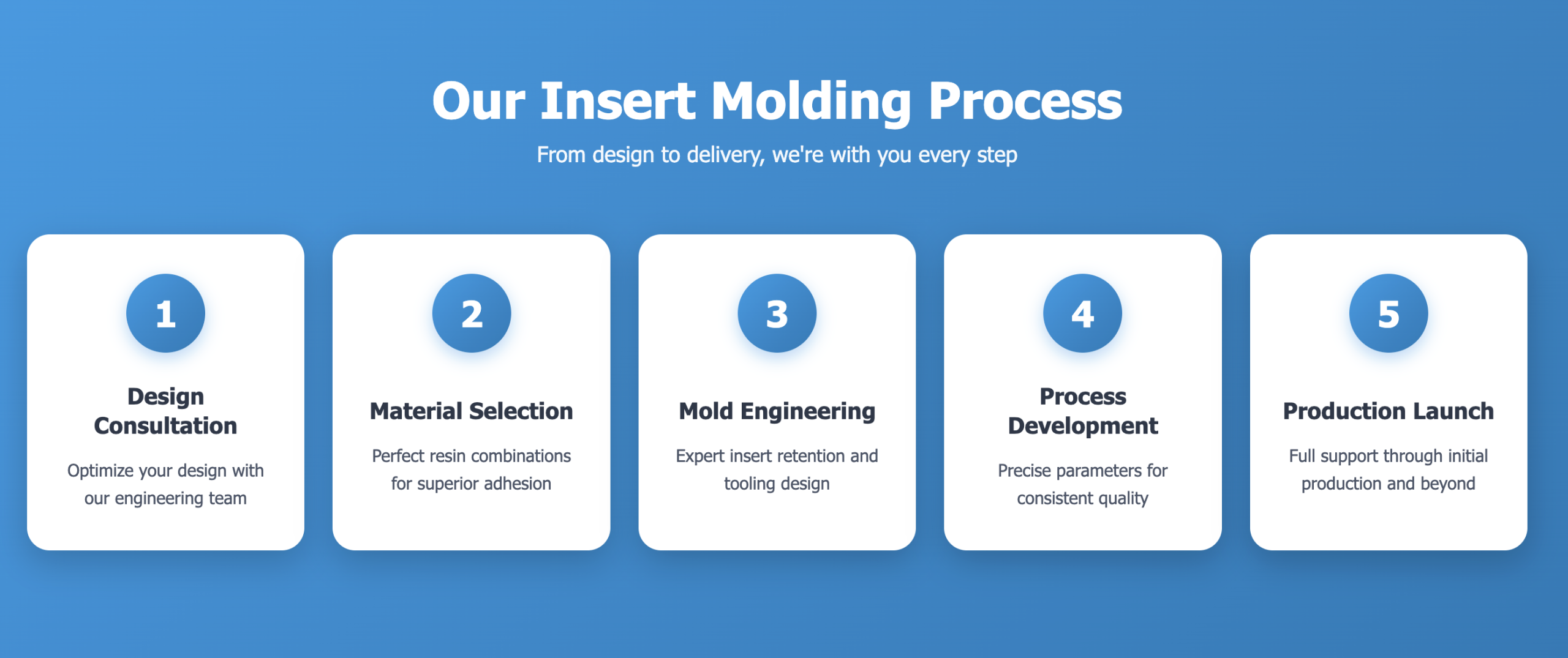

AdvancTEK engineers have extensive experience using the insert molding process and helping our customers find solutions to design challenges. From early design, to mold construction, to product launch; AdvancTEK can help assure your product launch is a successful one.

Our Comprehensive Process

Our collaborative approach ensures potential challenges are addressed early, reducing time-to-market and minimizing costly redesigns.

SCHEDULE A DESIGN CONSULTATION

Insert Molding Success Stories

“I really enjoy working with them. Everyone is very friendly. Nothing but good things. They are honest. If there are issues, they address them right away so we can find a solution.”

Frequently Asked Questions About Insert Injection Molding

How does insert molding affect part cost and tooling cost compared to adding inserts in a secondary process?

If design is considered early in the process tooling costs can be minimized and complexity of the design can be reduced. There is typically some cost increase to tooling versus standard mold build but is it reasonable and far outweighs the cost of secondary labor and fixtures required.

What materials are typically used for overmolding and insert molding?

Resins used in overmolding can range from crystalline materials to amorphous materials. Inserts that are overmolded are typically brass or stainless steel but can vary based upon the end use application.

Ready to Enhance Your Product with Insert Molding?

Our facilities in Concord and Saltillo are equipped with advanced insert molding capabilities to bring your project to life. Whether you’re developing a new product or improving an existing design, our engineering team is ready to help you achieve superior results. Contact us today to get started!

CONTACT OUR INSERT MOLDING EXPERTS TODAY